Energy Management — Canfor Pulp

Our modern kraft mills operate as large-scale biorefineries, allowing us to efficiently manufacture premium pulp products while producing clean energy. We use steam generated in our boilers to generate electricity and heat our operations, and export surplus power to the BC electricity network.

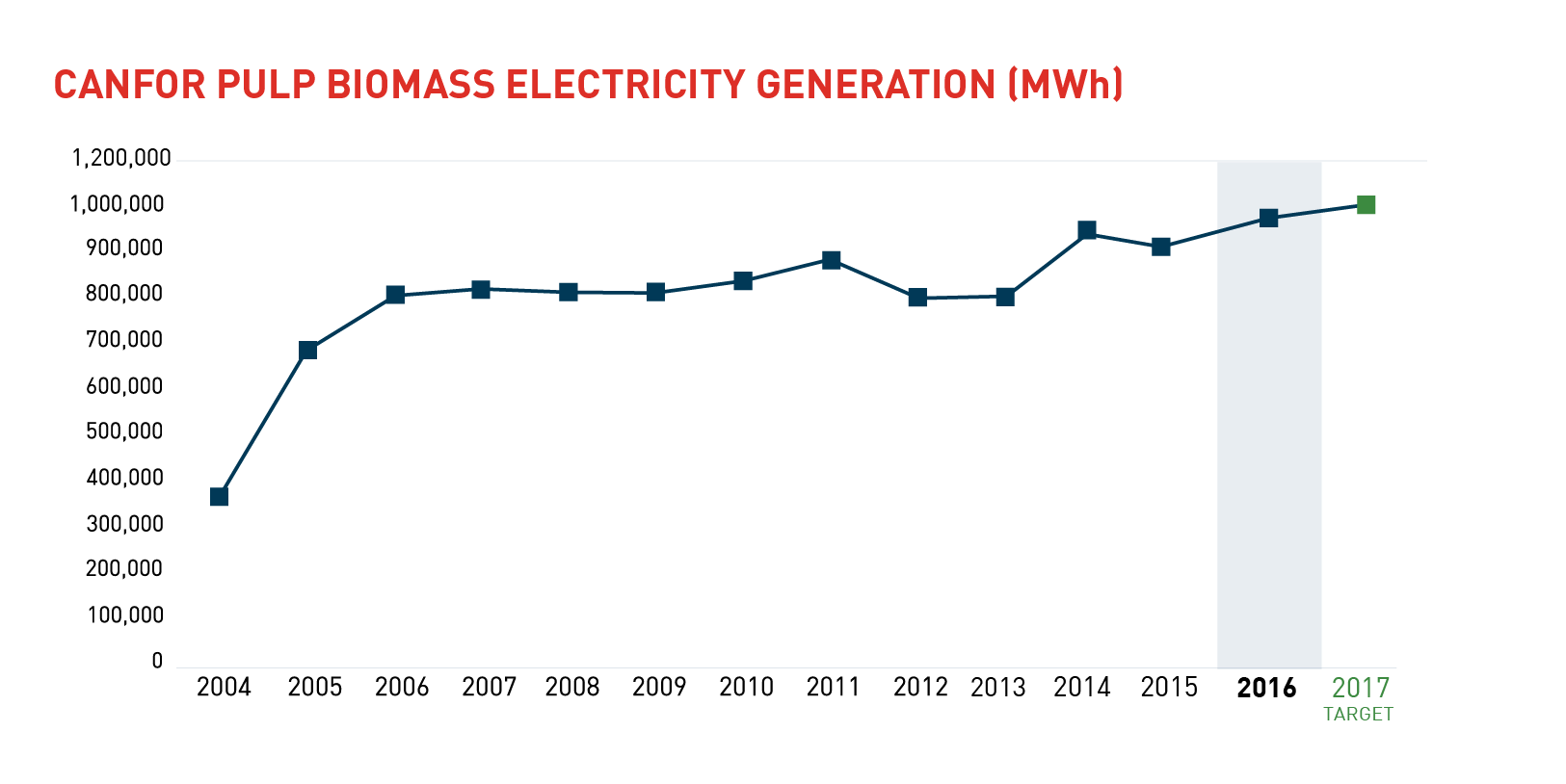

Canfor Pulp established a new record in 2016 with the generation of 985,741 MWh from the four biomass turbine generators at our mills in Prince George – and are nearing our target of one million MWh annually. Continued investment in thermal energy efficiency in 2016 enabled the Intercon mill to increase its generation output by almost 5 MW.

Canfor Pulp generated 985,741 MWh of power from our three Prince George mills in 2016, and are closing in on our target of one million MWh/yr.

Canfor Pulp generated 985,741 MWh of power from our three Prince George mills in 2016, and are closing in on our target of one million MWh/yr.

In 2016, Canfor Pulp signed an agreement with Licella Fibre Fuels, an Australian energy technology development company, to form a joint venture under the name Licella Pulp Joint Venture. Licella has developed a catalytic hydrothermal reactor upgrading platform, which converts biomass into a renewable biocrude, which can then be refined in a conventional refinery. Joint development work continued in 2016 as we work closer to the final viability analysis of operating at a larger scale and integrated into our existing kraft pulping process.

Canfor Pulp won a Canadian Industry Program for Energy Conservation Leadership Award (CIPEC) in the category of Employee Awareness and Training. We were selected for our significant achievements in energy efficiency and environmental stewardship, including turbine generator upgrades, updates to operating and maintenance practices, and capital investments to improve our biomass boilers.